Surfacing

– Welcome to the Ball of Confusion! Surfacing

– Welcome to the Ball of Confusion!

Good Surfacing is all about Organization,

Clarity, and Memory

When faced with the enormous challenge

of learning to create complex Pro/Engineer models using surfaces,

the biggest challenge is not figuring out how to create features

– you can look that up in any manual or online tutorial. The

biggest challenges are being able to plan, visualize, and keep track

of what is going on.

Why?

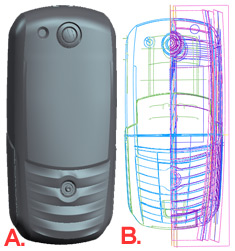

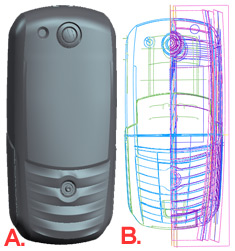

- With solid modeling, its reasonably

clear what you’re doing. You extrude a boss – you

see the boss. You make a hole – you see the hole. Since

you can’t put solid features on Layers, its 100% WYSIWYG

- What You See Is What You Get. Because most of the time, during

the building process, a model that ends up looking like the Motorola

E1000 phone above, Fig.A, will look like the mess that is Fig.

B. Its most definetely not “what you see is what you get”.

Even with a very compact, well-organized model, it can be difficult

to clearly see what’s happening until the last few features.

If you unblank all layers, its totally impossible to figure out

what’s going on because your screen is now one big birds

nest of purple and magenta.

- Asynchronicity – Because

a feature’s references are frequently asynchronous. With

surfaces, you frequently need to go back in time (in the model

tree) to pick up references. Generally, you will have larger,

cleaner surfaces available for use earlier in the model build.

Because these references are not related to other features around

them,

- Because, frequently you end

up modeling negative space for boolean merges. ie. Creating the

shape of a feature you want to make a cut with.

So, what is the best

way to manage the confusion?

Well, my high school Latin teacher,

Aubs, said something that stuck with me forever, and, don’t

worry, it wasn’t about Latin. He said that in order to memorize

the dry, dead language of the past that is Latin, we should do

whatever we need to in order to make it memorable. So he suggested

we should use highlighter or stickers, or lots of different colours,

or arrows, or doodles. Whatever we need to do in order to make

the words personable and signify something to us.

This approach works just as well

for Pro/Engineer as it does for Latin. And it is especially useful

for complex surfacing.

So…

- Create a layering scheme

that makes sense to you – and use it! Create friendly

and simple layer names and and automate the placement of features

onto those layers where possible. For example, I always have a

Surface Layer and a Curve Layer where objects are automatically

placed. Additionally, I manually place parting surfaces on a Parting

Layer and construction surfaces on a Construction Layer. Then,

functional features are placed on appropriate layers: there will

be a Front Housing layer, a Cooling Fan layer, a Battery layer,

etc. This makes it extremely easy to only show those items on

the screen that are relevant to what you are working on.

- Minimize feature

count – the fewer

features you have, the fewer you have to remember! Believe me,

you’ll appreciate this as you get older and your memory

turns to mush! However, there are many other benefits to low feature

count: fewer surface patches create better relationships with

child features; a small model is generally a well organised (keeping

it small forces you to think about structure); small models regenerate

faster.

- Colour your features

– surfaces and datum curves can be coloured although surface

colour is only visible in shaded mode. This works well for standalone

models. Beware that coloured surface features will propogate this

colour through an external merge to the target parts when using

the Master Model technique. This can be annoying. At this stage,

I normally remove colour from all objects in the Master at that

stage.

- Name your features

in the model tree to provide clarity. This is mainly

for your benefit, but it may be extremely useful for downstream

users and the poor sod that has to tweak your model while you’re

off on your holidays. Another major benefit becomes apparent if

you ever need to hand-off your model to a remote location. Named

features become street signs when walking another user through

your model on the phone. For example, you may have many offsets

in your data. Wouldn’t it be nice if the main offset for

the core side geometry were named “Main-Offset-Core”

or something similar, rather than “Feature 121”? You

will now find yourself describing other features with respect

to this named feature.

- Create surface

merges as soon as possible after surface creation.

This does two things for you. It immediately reduces the number

of quilts by one, and it associates the merge with the surface

through its relative position.

- Put features in a meaningful

order and group them appropriately. Groups aren’t

just for bosses with on-the-fly datums. Use groups to slice up

the model tree into nice logical chunks. Although they don’t

reduce feature count, they do reduce apparent feature count and

improve organization. Its quite nice to open a part and find most

of the features grouped in a functional mode similar to the layer

scheme described above. For example, in a 200 feature model, there

might be 7 or 8 groups of features named, Base-Curves, Base-Surfaces,

Front-Housing, Rear-Housing, Battery-Door, etc.

- Split out complexity

– go to master or copy geom – multiple levels ie.

If you have 300 features and you have a main surface quilt plus

secondary details, you could create a simple model that only contains

the initial datum curves and primary enclosure quilt (pic example).

Then merge (or copy geom) this part into the secondary model.

This does’t reduce feature count – the total will

still be the same – but it does simplify the model. You

may now have one initial model with 100 features, and a secondary

model with 200 features.

In a perfect world, you would

be able to model blind. Well almost blind. Immagine being able

to look at the model tree and not the geometry and being able

to see the product grow from feature to feature. What does it

take to do this? You just need to implement the suggestions

above and be very consistent with the order and way you build

features. If you do that, your model tree will communicate information

to you in this kind of way...

- Surface B follows Datum curve

A, so it probably is a child

- Surface Merge C follows Surface

B, so it must be related

- Features A through F are grouped

together and labeled "Handle" so they must form the

handle of the product.

- Copy Surface X is named in such

a way that I know that this is where I copy the outer surface

to close the quilt for the handle which is going to happen in

the next group of features.

Do you remember the film, the

matrix? If the Tank character can look at a stream of numbers

and letters on the screen and interprete these into people and

cityscapes, then you shouldn’t have any problem at all

with relatively simple 3D geometry.

|

Surfacing

– Welcome to the Ball of Confusion!

Surfacing

– Welcome to the Ball of Confusion!