|

|

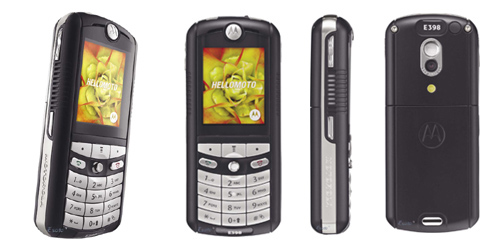

Motorola | |||

01

FIMER welder

|

|

|||

"Meticulous

Surfaces for Mobiles" The

Challenge |

||||

|

||||

| The

Solution Motorola use a dedicated Surfacing Engineer for each new development program. This engineer creates all the external parts for the phone. He works in the functional space between the Industrial Designer and the Engineering team. He is responsible for interpreting the 2D drawings from the Designer and creating 3D data for Engineering and Manufacturing that meet all mechanical requirements. Typically, this means providing minimal clearance with internal components and creating fully drafted surfaces that are easily mouldable. In order to create a complete database of all parts in a complex assembly, Motorola and I.D.milano use a procedure called the Master Model technique to guarantee a perfect fit between all parts in the assembly. Basically, a surface model is created that represents the entire external surface of the phone. Subsequently, all the individual parts reference this "master" in such a way that any changes made to the master will also automatically update all solid parts in the assembly. Experience and using the appropriate techniques enables I.D.milano to guarantee delivery of a new database for prototyping within 2-3 weeks. |

||||

|

||||

| The

Result Together Motorola and I.D.milano have completed several programs though to production including GSM, UTMS, and Smartphoness. In addition I.D.milano has worked on a number of advanced concepts for Motorola Consumer Experience Design and collaborated with Motorola facilities in England, France, Italy, and the United States |

||||

|

||||